If you want smooth, predictable shifting without swapping the whole transmission, you’ve come to the right place. At Klifex, we provide parts for transmission gears, seals, bearings, sleeves, and targeted transmission repair kits that fix the usual problems quickly and affordably. Match parts by transmission model or OE number, replace the worn pieces, and you can usually restore proper function without a full rebuild. Here’s what this selection includes:

- Fitment first: matching by transmission model or OE number for a correct fit.

- Parts for manuals and automatics plus AWD driveline components.

- Seal kits, bearing kits, sleeves, gear parts, and gearbox or driveline belts.

- Mechatronic adapters, automatic transmission repair kits, speed sensor kits, transfer case servo motor repair kits, and flange tailpiece rear gear assemblies for BMW.

Need help identifying the right transmission repair kit? Send us your VIN and symptoms, and we will recommend the correct parts list.

What the Parts Do and Why Small Wear Causes Big Problems

Gears carry torque through the box. Bearings support shafts and keep rotation true. Sleeves and bushings maintain alignment. Seals keep fluid in and contaminants out. Think of them as a team: when one player is off, the whole performance drops. A quick, accurate inspection followed by the right transmission repair kit saves time, money, and headaches down the road.

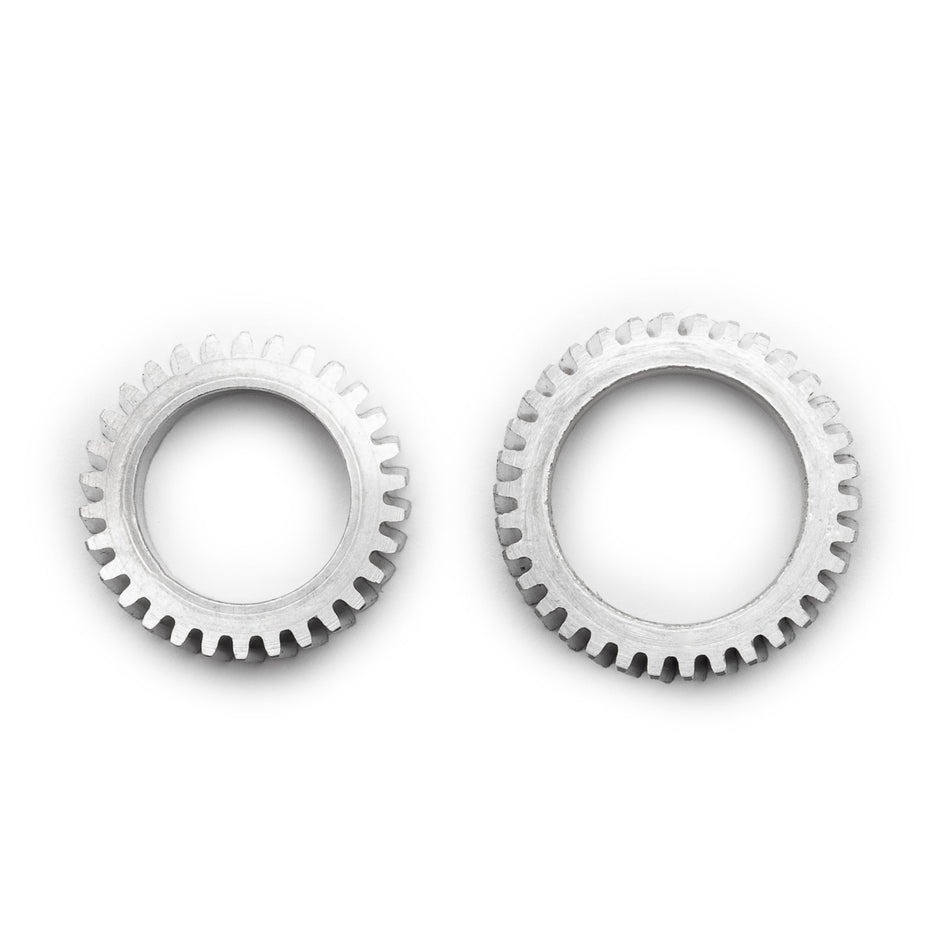

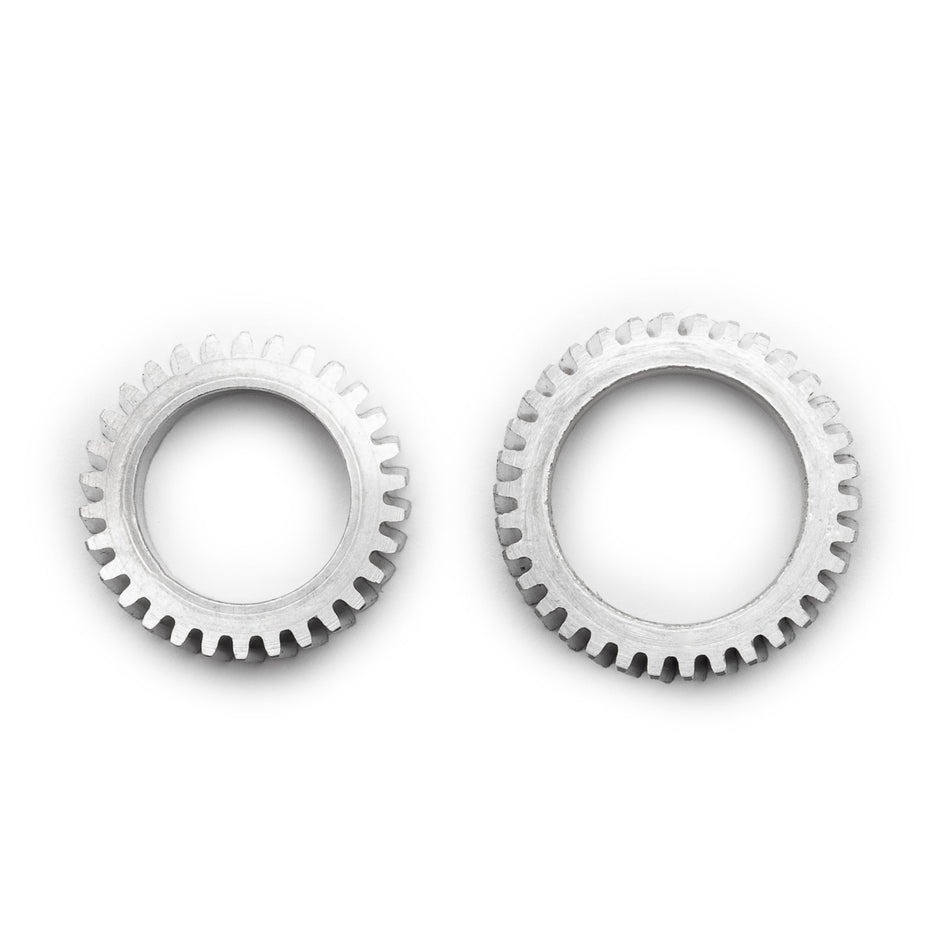

Types of Gears and Where They Belong

Manual transmissions typically use helical gears for quieter operation and synchronizers to match speeds during shifts. Automatic transmissions use planetary gearsets to create multiple ratios in a compact package. Knowing which family your transmission belongs to speeds up finding the right transmission gears or planetary transmission components when shopping.

Symptoms Mapped to Likely Causes

Start with what the car does and run a few basic checks to narrow the cause before ordering parts:

- Humming or whining under load often indicates gear wear or failing bearings.

- Vibration during shifts points to excessive backlash or worn sleeves.

- Crunch on engagement in a manual usually means synchronizer wear.

- Harsh or delayed automatic shifts can be hydraulic, electronic, or mechanical in origin.

A fluid and filter check is a good first step before parts orders. Correct diagnosis prevents wasted transmission kit parts and repeat shop labor.

What You Will Find Here

This page focuses on the components you need for repeatable repairs. Typical items include transmission rebuild kit components such as seals and sleeves, bearing kits, specific gear parts, and EPS or drive belts sold to exact length and profile. Not every transmission gets a full overhaul kit here, but the common wear items are covered for many popular transmissions. Product highlights:

- Mechatronic adapter. This is a small but essential part used when servicing mechatronic units on certain BMW and Land Rover models.

- Speed sensor kit. Helps restore accurate speed and shift logic where a faulty sensor causes erratic shifts.

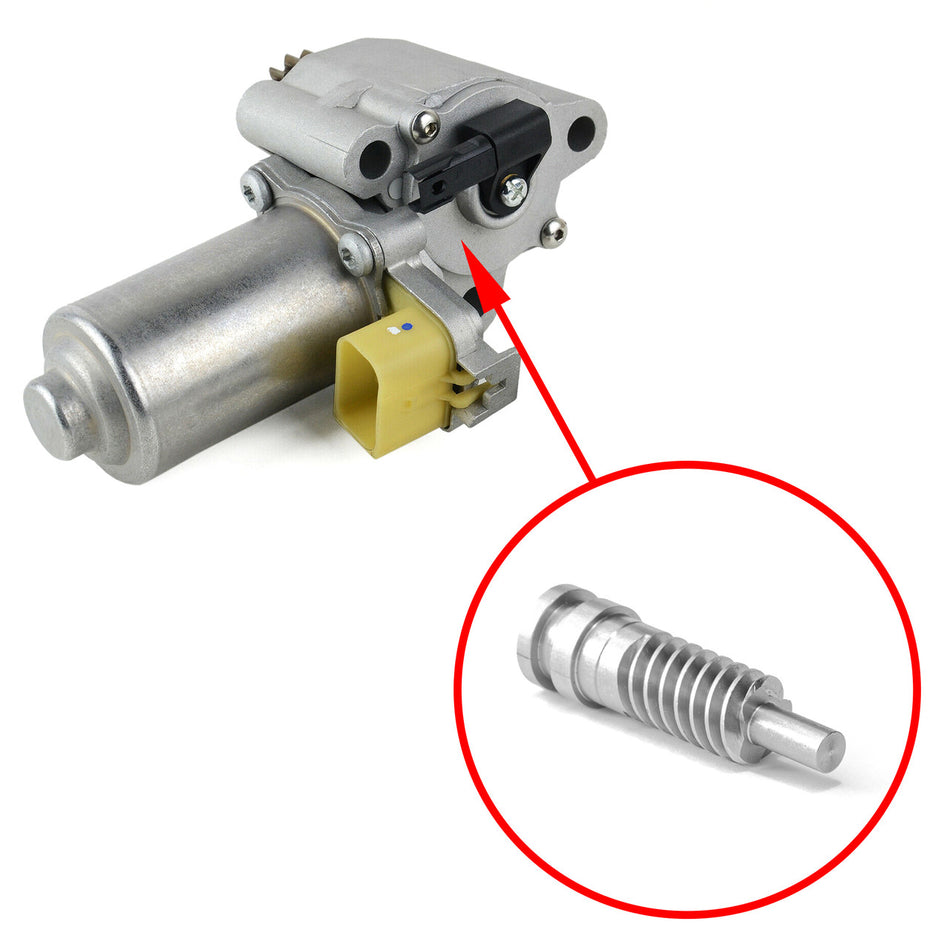

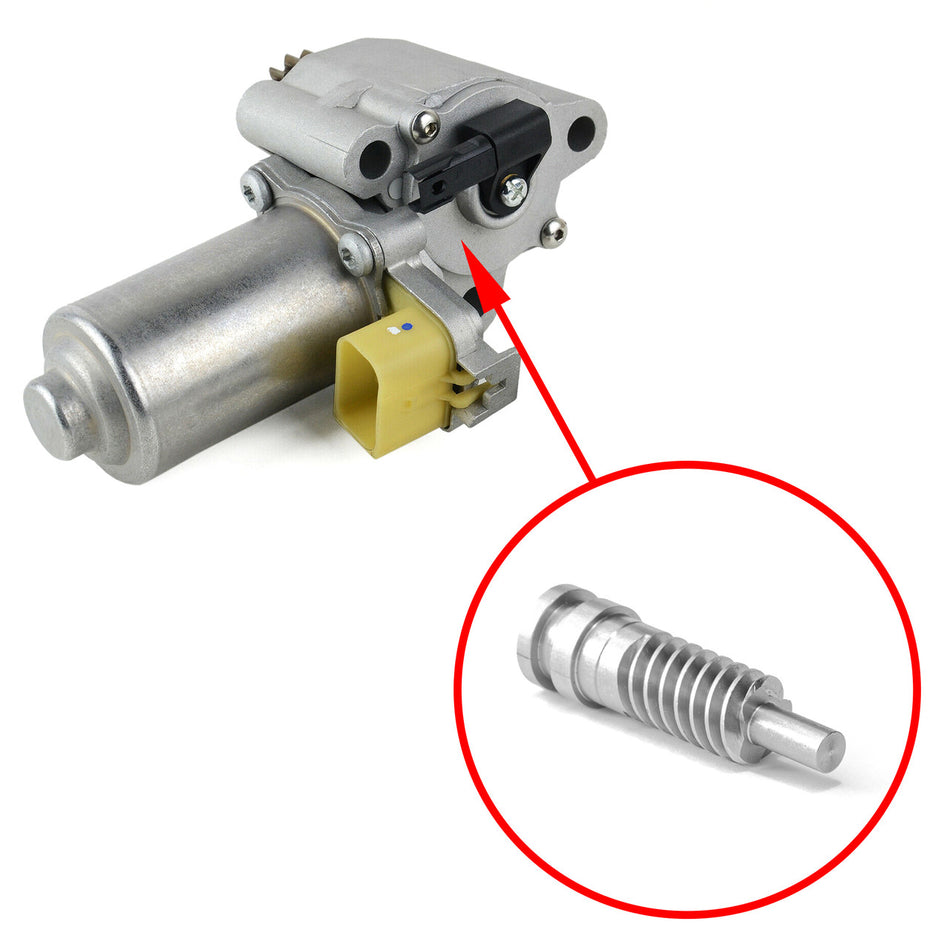

- Transfer case servo motor repair kit. Useful for AWD troubleshooting where the transfer actuator is failing.

- Flange tailpiece rear gear for BMW. A robust replacement for specific rear drive components showing wear.

Add the correct OE part plus the matching seals and bearings, and you’ll complete the job in one go. Fit the mechatronic adapter, swap the speed sensor kit or transfer case servo motor repair kit, or install the flange tailpiece rear gear and enjoy quiet, predictable shifts.

Repair Kit Versus Rebuild Kit Versus Upgrade Kit

A transmission repair kit targets a specific failure, such as leaking seals or worn sleeves. A transmission rebuild kit is broader and intended for a teardown and reassembly using a wider set of replacement items. Upgrade kits change gearing or strength and are a different category. For most shop jobs, the repair kit restores function without the time and cost of a rebuild.

Ordering and Support In the USA

Use the brand filters to narrow options for BMW, Mercedes, Ford, and other brands. If you want faster confirmation, send us your VIN and a photo, and we will advise the correct automatic transmission repair kit or individual components to finish the job in one session. Check the Shipping Policy page for transmission kit pricing and delivery details.

In stock

In stock

In stock

In stock

In stock

In stock

Out of stock

Out of stock