63 Products

Injectors are tiny workhorses. A worn seal or a slightly degraded nozzle turns precise fuel delivery into drivability drama. Here you’ll find practical fuel injector repair kit options, fuel injector rebuild kits, and fuel injector O-ring kits designed to restore sealing and spray performance without replacing the entire assembly. Match the parts by injector code or VIN and pick the right kit, such as:

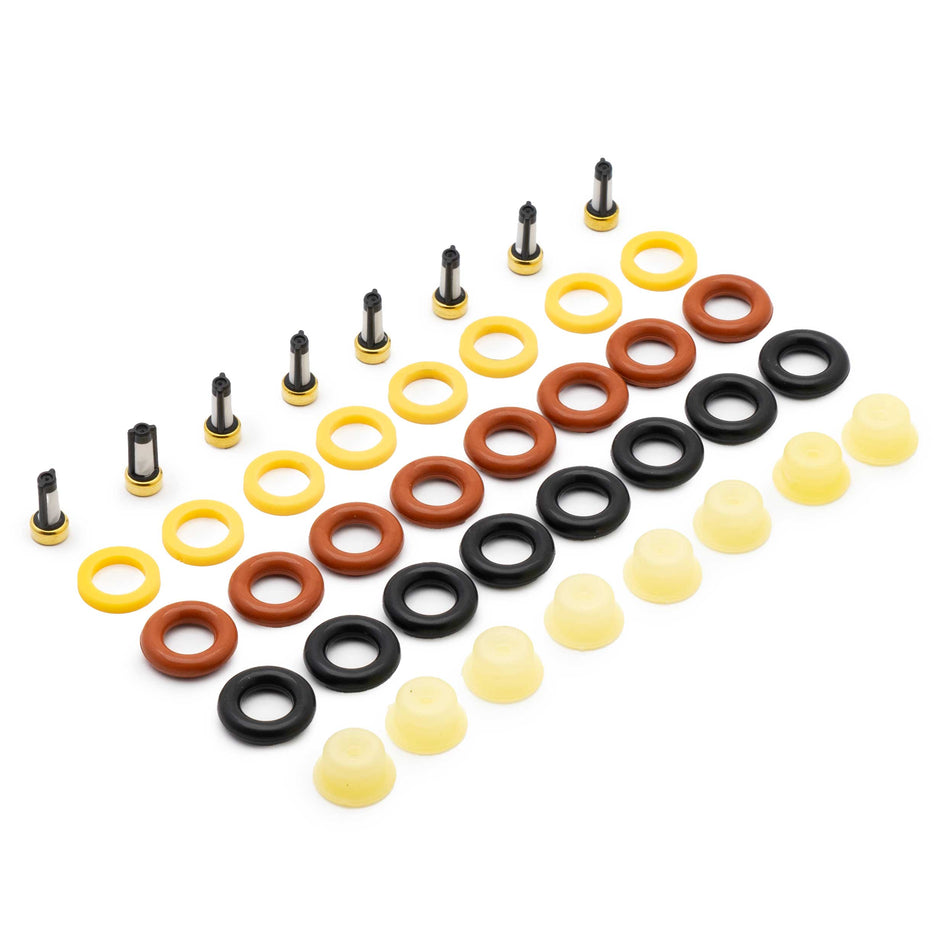

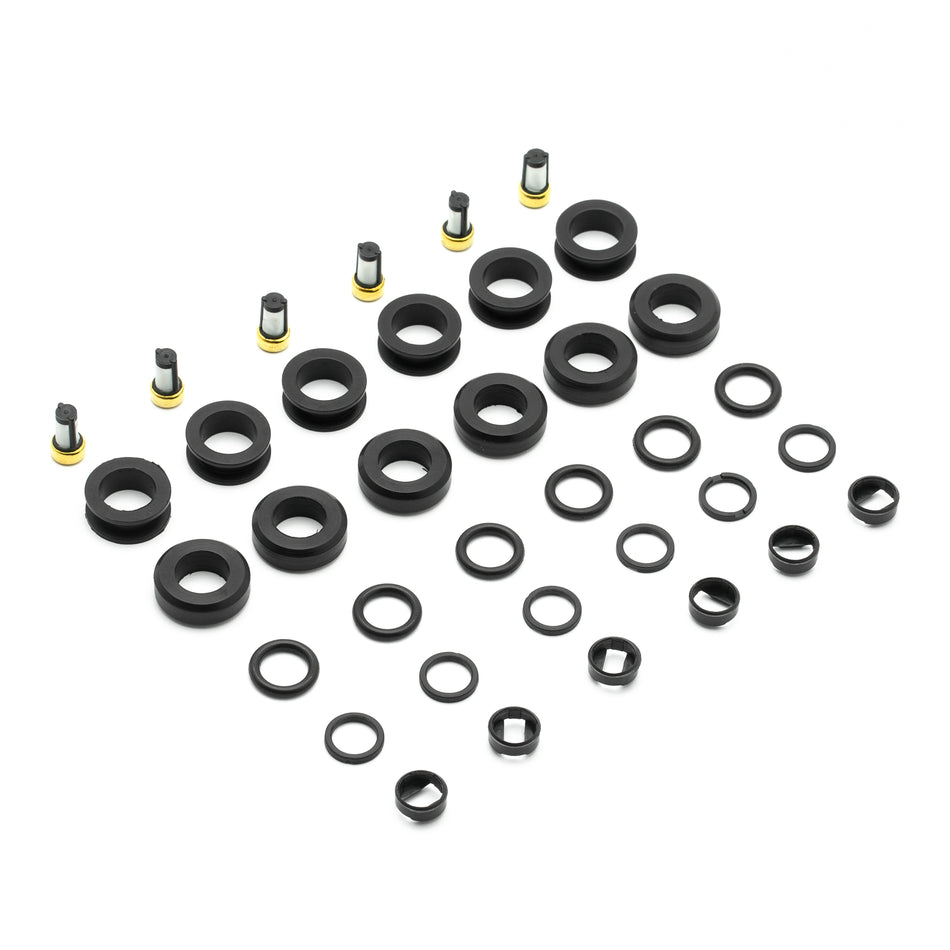

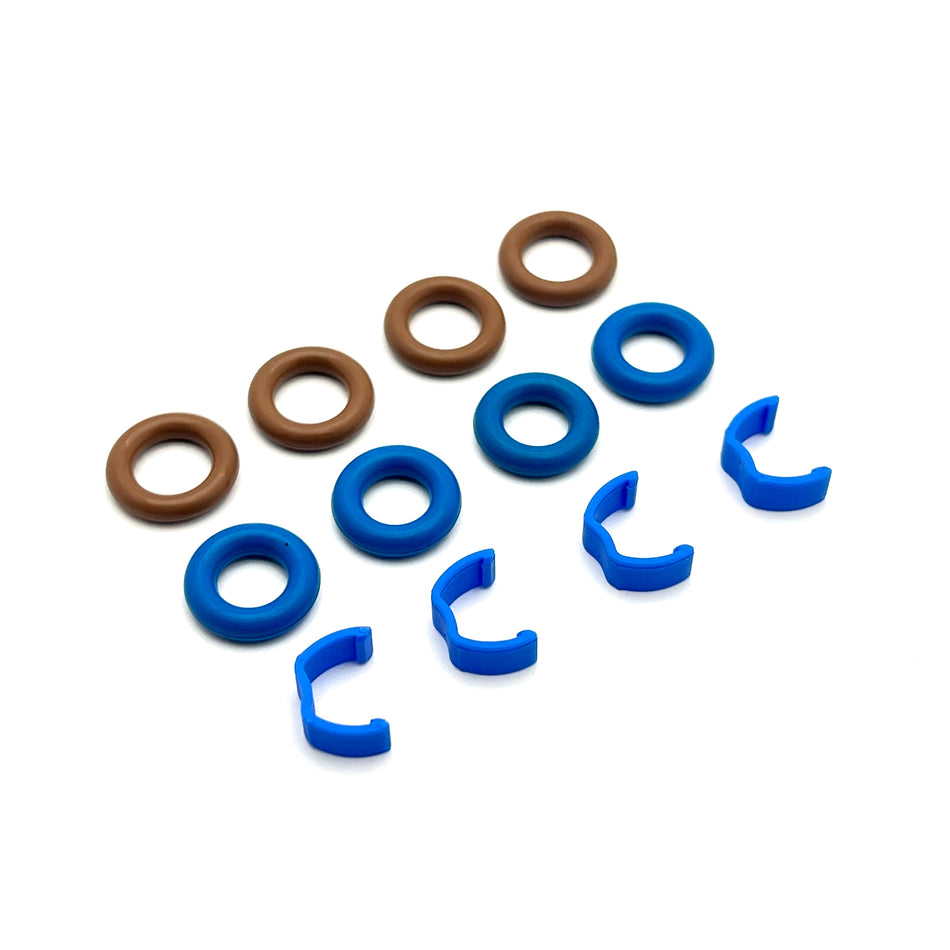

- Seal kits and O-rings sized to original dimensions.

- Nozzle repair packs for restoring spray geometry.

- Rebuild kits that include springs, seats, and small hardware.

- Fitment filters for popular brands.

Use the brand filters and part numbers to find the exact fuel injector seal kit for your car.

What an Injector Repair Kit Actually Is

A fuel injector repair kit is a focused set of wear parts intended to restore sealing and nozzle performance. Some kits are essentially an injector O-ring kit for leaks at the rail or nozzle base. More comprehensive injector rebuild kits may include nozzle tips, pintles, springs, and internal seals when the spray pattern or mechanical movement needs attention. Kits are appropriate when the injector body and solenoid are intact, and the issue is mechanical wear or sealing failure.

Why Nozzle Condition Matters for Combustion

The nozzle controls atomization and spray pattern. Changing the orifice, needle lift, or seat geometry can lead to a drop in combustion quality. That means rough idle, more soot, poorer fuel economy, and higher emissions. Diesel nozzles operate at much higher pressures and require precise seating.

Gasoline direct injectors are prone to deposit buildup that distorts the spray, requiring both cleaning and correct sealing to restore performance. Fixing nozzle and sealing problems early prevents catalyst and particulate filter damage and improves drivability.

Diesel Versus Gasoline Injectors: What the Kits Do

Diesel injectors endure extreme pressures and mechanical stress. Diesel injector nozzle repair kit options commonly include hardened seats and specific sealing washers designed for high pressures. Contamination and varnish are frequent problems. Cleaning plus a nozzle seal kit often resolves the problem when the injector body is sound.

Gasoline injectors, including TDI and port types, suffer from carbon and varnish. Fuel injector repair kit choices for gasoline engines often focus on O-rings, pintle caps, and strainers. For TDI injectors, consider combining a seal kit with professional ultrasonic cleaning when deposits affect spray.

What’s in Seal Kits and Rebuild Kits

Seal kits generally include O-rings, sealing washers, and small caps. Rebuild kits add nozzle seats, springs, and internal seals as needed. High-quality kits use fuel-resistant elastomers and match OE dimensions for reliable sealing. A fuel injector O-ring kit is a simple preventive or leak repair pack, while a rebuild kit targets internal wear. Kits do not include ultrasonic cleaning, flow calibration, or electronics. If the injector’s solenoid is burned or the housing cracked, plan for replacement or a professional bench rebuild.

How to Choose the Right Kit

Identify the injector part number from the body, rail stamp, or VIN. Confirm the failure with basic checks: fuses, connector voltage, and a simple flow or spray check if possible. Use site filters to narrow by brand and part code. Choose a seal kit for leaks and a rebuild kit for degraded spray or mechanical wear.

Symptoms and Diagnosis

Start with a quick look and basic checks before buying parts. Observing the symptom first and doing a short diagnostic run prevents wasted parts and repeat visits.

- Rough idle or misfire: likely spray pattern degradation or clogged nozzle. Check error codes and swap connectors to see if the fault follows the injector.

- Fuel smell or visible leak: likely O-ring or sealing washer failure. Pressure test the rail and inspect the boots.

- Increased fuel consumption: possible leaking nozzle or partial atomization. Verify return flow and measure injector flow if possible.

- Black smoke on diesel or hesitation on gasoline: poor atomization or stuck injector. Check nozzle spray and fuel pressure stability.

Confirm faults with a leak or flow test when possible. Replace seals only after verifying a spray or sealing fault. When unsure, bench test the injector or send it for professional cleaning and flow calibration first.

Installation Overview and Safety Note

Work clean and avoid introducing particulates into the injector bore. Replace seals with the correct lubricant and test injectors on a bench if possible before reinstalling. After installation, pressure test and run the engine to verify sealing and spray. High-pressure fuel systems require proper procedures and PPE. If you lack the right test gear, consider a bench service to avoid repeated repairs.

Purchase Injector Repair Kits Online

A small kit often solves a big problem. Send your VIN and injector part number to Klifex for a quick match to the right fuel injector repair kit or injector nozzle repair kit, and list any additional seals or hardware you should order to finish the job cleanly and confidently.