82 Products

Vacuum Pump Repair and Rebuild Kits for Garage and Track

If your brakes feel soft, oil is pooling at the pump flange, or vacuum-dependent systems act up, don’t reach for a full replacement right away. Most failuresare due to wear or seals, and a correctly chosen vacuum pump repair kit or vacuum pump rebuild kit restores function at a fraction of the cost.

What a Good Kit Contains and What to Check

A solid vacuum pump kit includes vanes or diaphragms, oil seals, O-rings, bearings, bushings, springs, and the small hardware techs always search for mid-job. Electric pump kits add brushes or rotor parts when needed. When you buy a kit, check for oil-resistant elastomers and hardened bushings, and match the kit to the pump model. Klifex listings include items such as a vacuum pump diaphragm for BMW N55, and a vacuum pump check valve for BMW N46 and N42.

Practical repair flow:

- Confirm the pump model and order the right kit. Don’t guess.

- Drain oil, tag hoses, remove the pump, and clean external grime.

- Disassemble and inspect the rotor, bore, and shaft for scoring or heat damage. If housing or rotor is badly damaged, replacement may be more economical.

- Fit seals first if you only see leaks; if the vacuum remains low, fit the rebuild kit and replace vanes and bearings.

- Reassemble to correct clearances, use the specified oil, bench test vacuum and noise, then verify brake booster vacuum after refit.

Change pump oil on schedule, inspect seals regularly, and replace filters where fitted. On electric pumps, check brushes and connectors. For turbocharged and diesel engines, shorten inspection intervals. Reusing old seals and skipping torque specifications are leading causes of repeat failures.

Choosing the Right Kit

Match the repair to the symptom: start with a seal kit for visible oil weeps, step up to a rebuild kit for low vacuum or noisy internals, and pick shop or performance kits when the application demands it. The goal is the smallest, most reliable fix that stops the failure from returning.

Quick checklist before you order: confirm pump part number, include a desiccant or filter if the system has moisture, and add a small O‑ring/hardware pack to avoid extra trips. Different cars have different parts to repair. The same applies to pump kits, from the most basic one to AC.

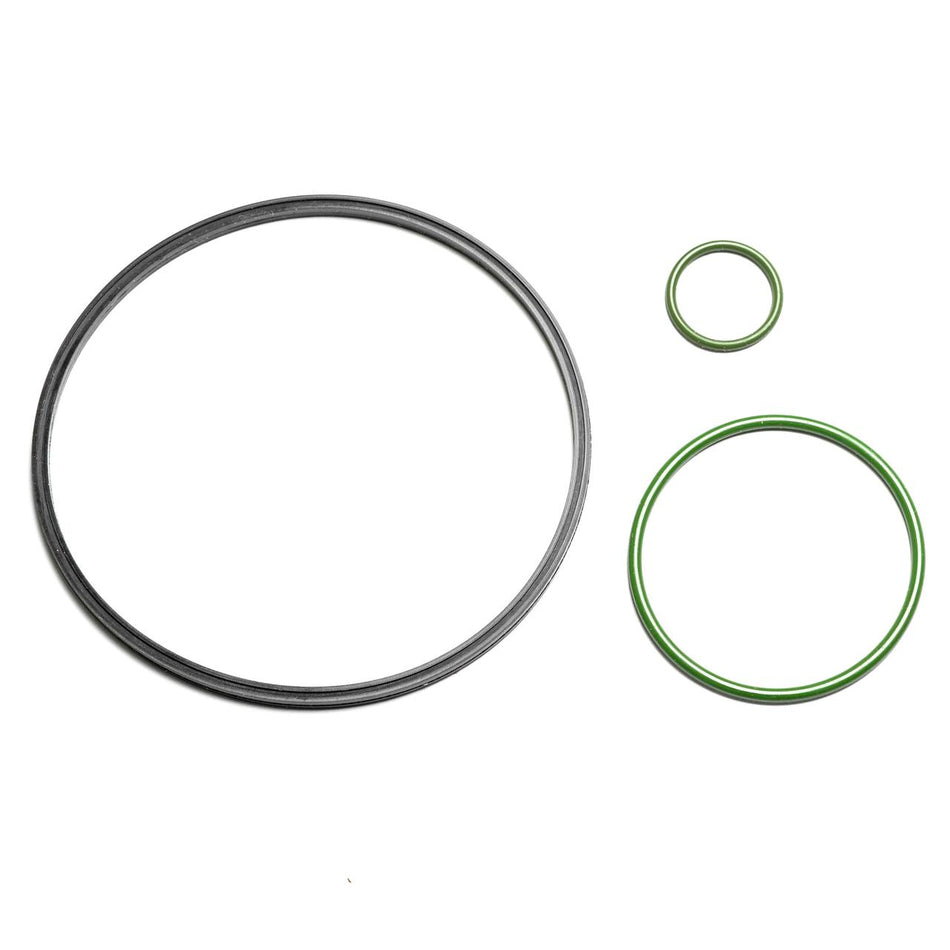

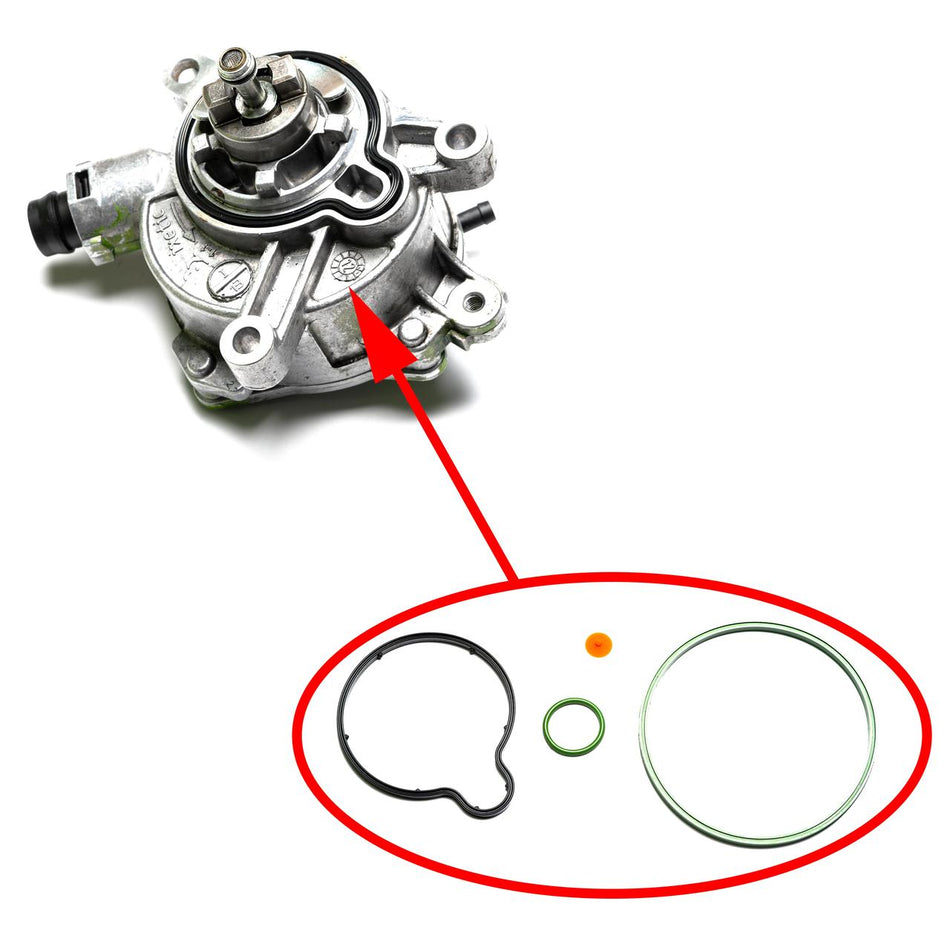

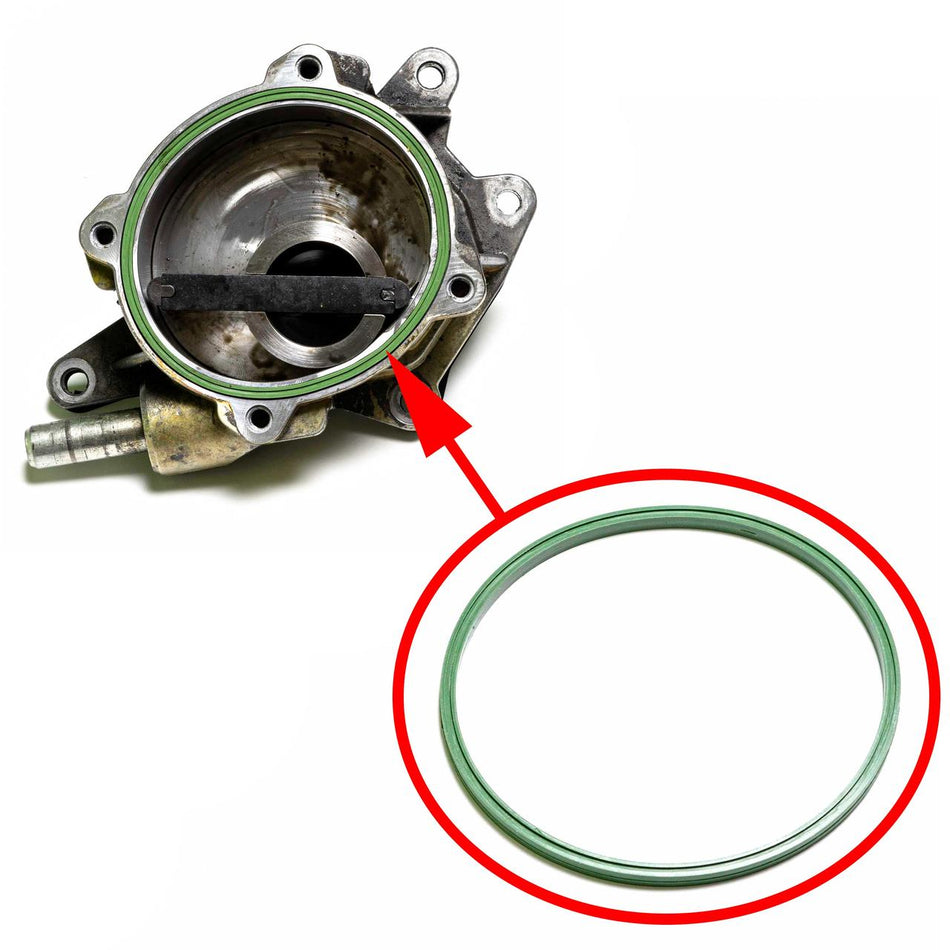

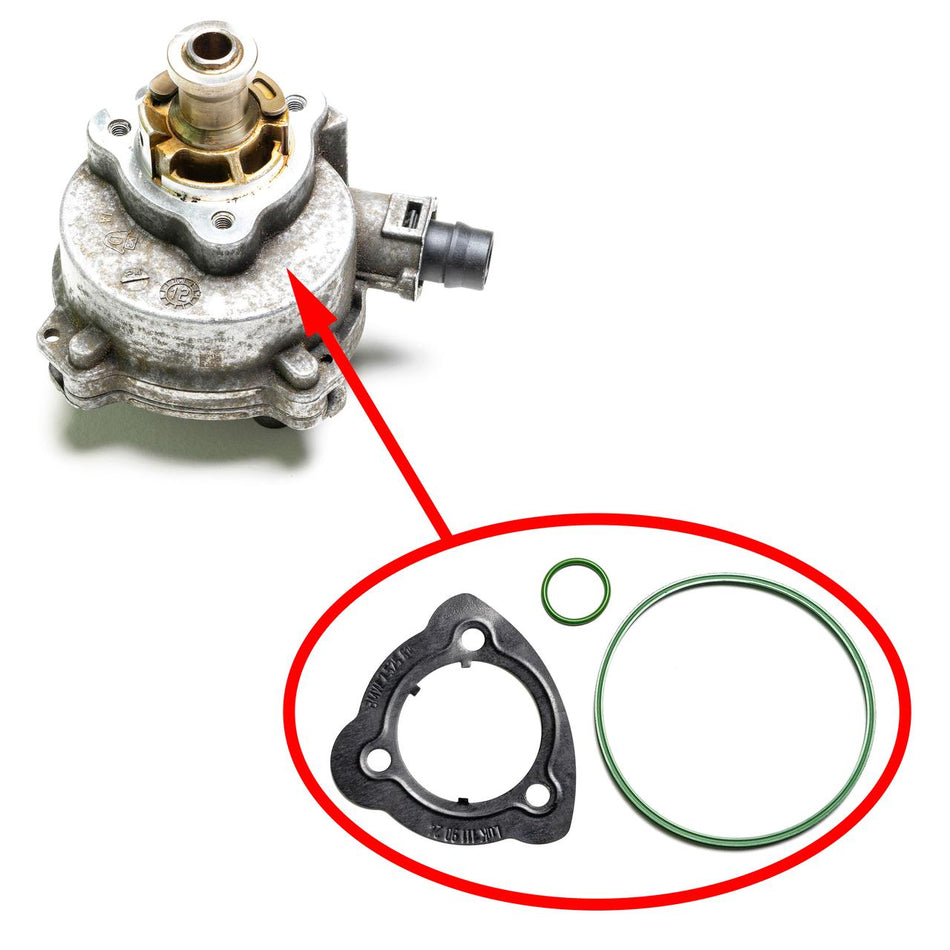

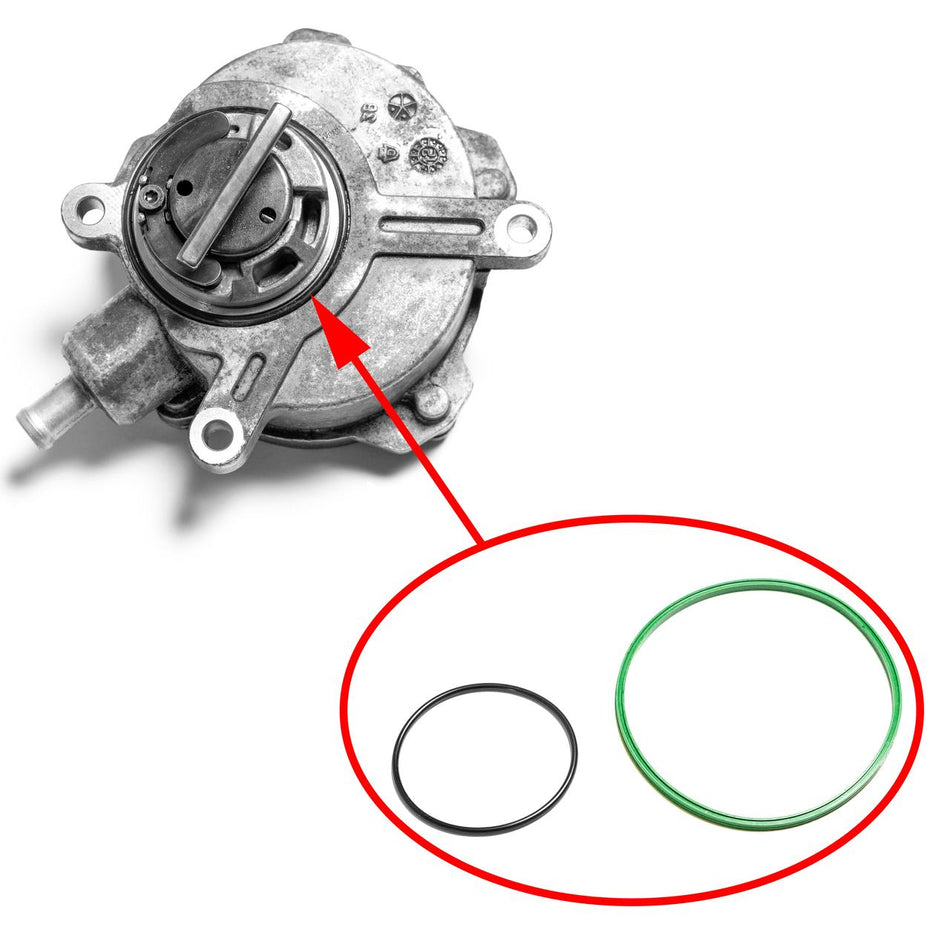

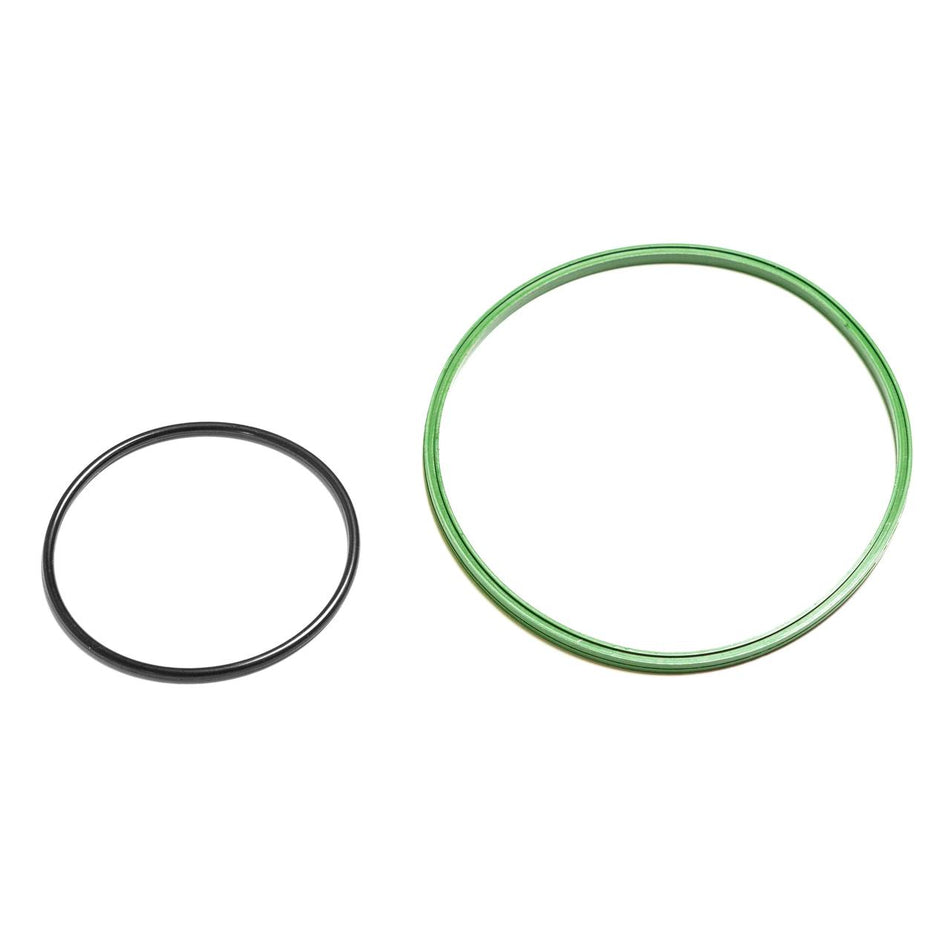

Vacuum Pump Seal Kits

When you find oil around the housing or at the mounting flange, start with a vacuum pump seal kit. These kits normally include shaft seals, O-rings, and housing gaskets. Common part examples include the BMW N20 and N26 vacuum pump gasket and the sealing gasket for the BMW vacuum pump (N52, N55, N54, and N51). Swap seals, clean the faces, refill the correct oil, and do a bench test. If the leak was the only problem, the pump will usually hold a vacuum after this quick service.

Vacuum Pump Rebuild Kits

If the vacuum is low, vanes are worn, or the pump grinds, step up to a full vacuum pump rebuild kit. Rebuild kits include vanes for vane pumps, bushings, bearings, springs, and internal seals. Klifex offers fit-for-engine kits such as the BMW N54 vacuum pump repair kit, as well as the BMW N55 and the BMW N47 repair kits. A proper rebuild requires a full strip, cleaning, measurement, and bench testing. When the rotor and housing are in good condition, a rebuild returns near-new performance.

AC Vacuum Pump Parts

Bench evacuation pumps used for AC service need their own parts. AC vacuum pump parts kits include specific vanes, motor brushes, and seals for the model of bench unit. If your shop pump won’t reach proper micron levels or is oily, replace vanes and brushes. Keeping AC parts like these in stock keeps throughput high and avoids failed evacuations.

Racing Vacuum Pump Kits

Performance and race engines run hotter and spin harder. Racing vacuum pump kits upgrade to reinforced vanes, high-temp seals, and heavy-duty bearings rated for sustained rpm. These kits are engineered for crankcase vacuum control under boost and long sessions on track. Install them with attention to oil choice and clearance settings, and expect a tighter maintenance schedule than street kits.

Hand Vacuum Pump Kits

A hand vacuum pump kit is a cheap, indispensable tool for leak tracing and bleeding brakes. These kits include a manual pump, gauge, and adapters for actuators and vacuum lines. After you fit a vacuum pump seal kit or vacuum pump rebuild kit, use a hand pump to isolate leaks and confirm line tightness before final reassembly.

Buy Vacuum Pump Kits Online in the USA

Klifex supplies vacuum pump kits packaged for the U.S. community. Kits undergo dimensional checks and bench testing. Product pages list pump models and compatibility so you can match a kit to the pump on the car. We ship coast to coast and provide technical notes and support for shops.

Order the right vacuum pump kit, get the correct oil and bench test supplies, and you finish the job in one session. Klifex offers fast US shipping, clear fitment, and guides to finish work the same day you receive your order.