The electrical system of a modern car powers the engine, lighting, ignition systems, climate control, multimedia, sensors, safety systems, and communications. Electrical components are key elements that convert, transmit, and regulate electrical energy, transforming it into mechanical action or a signal for the controller.

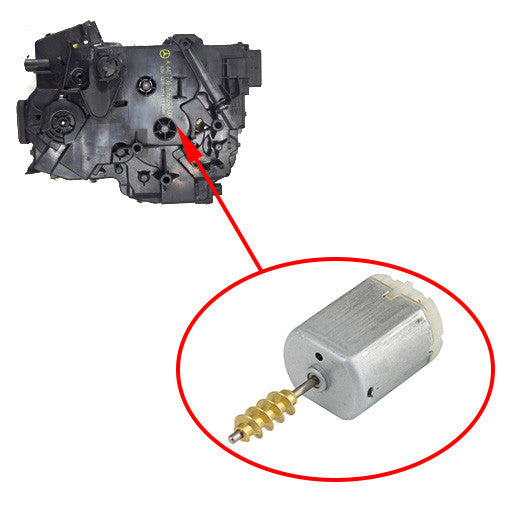

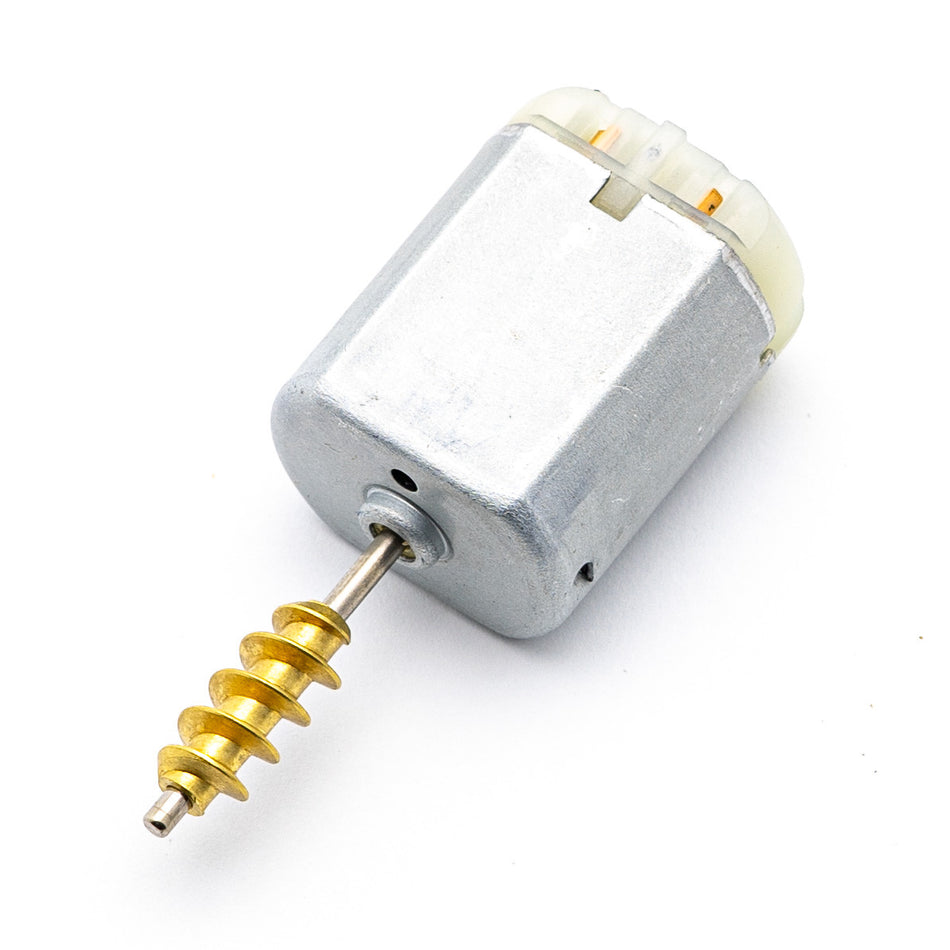

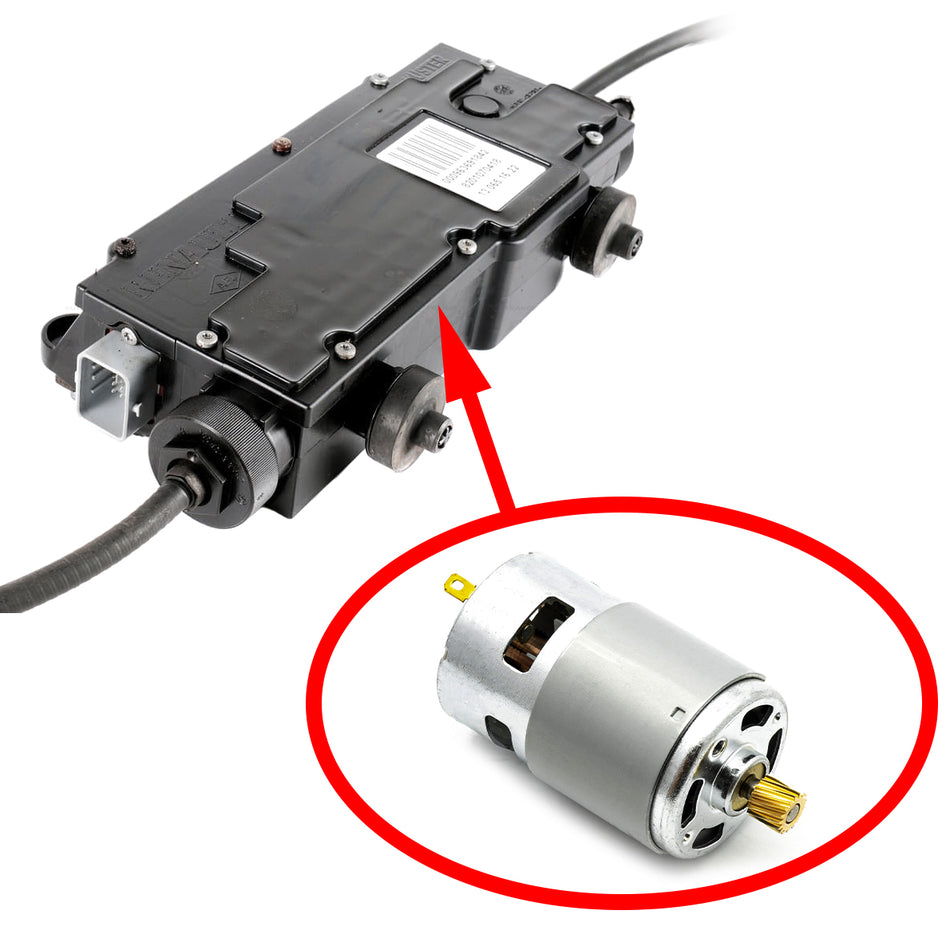

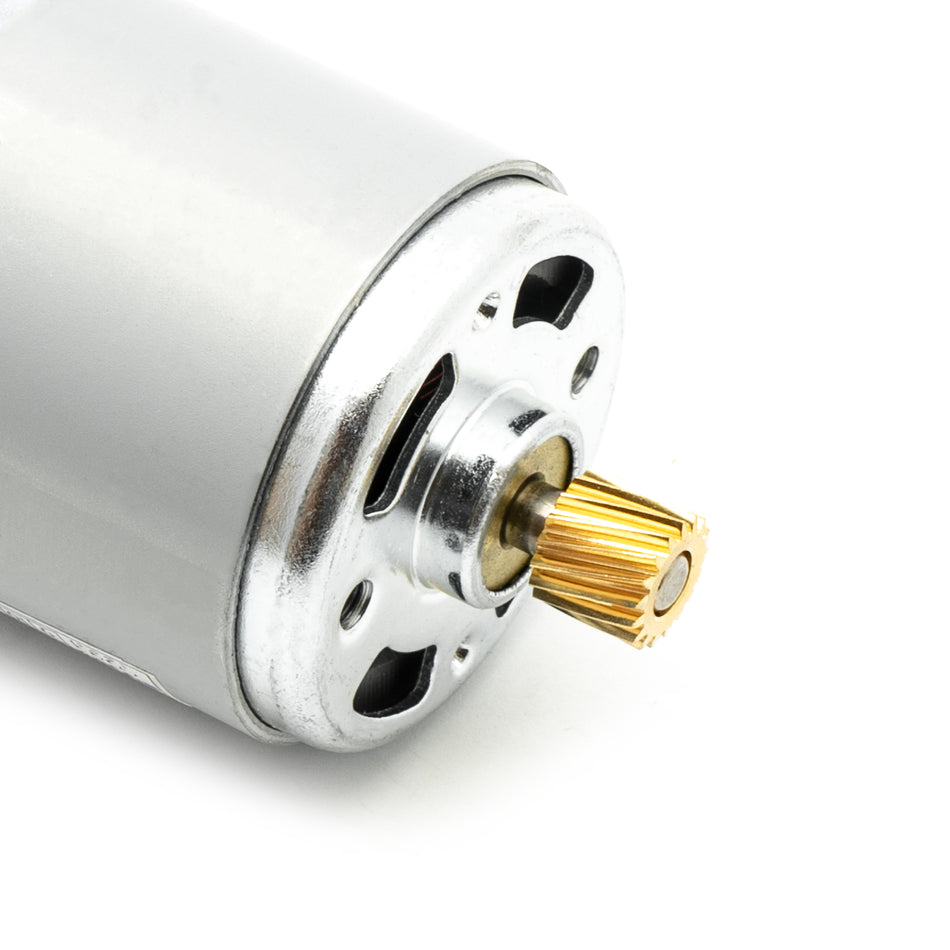

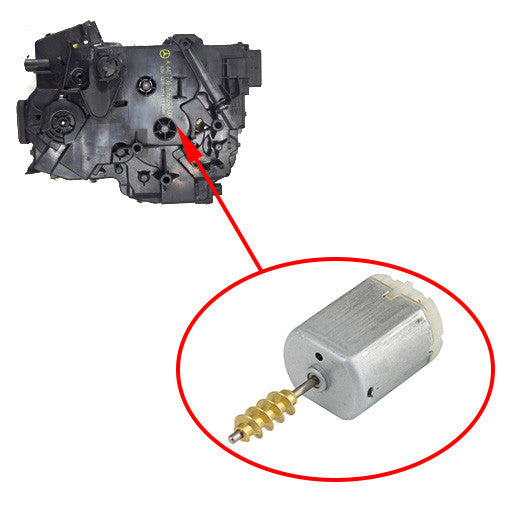

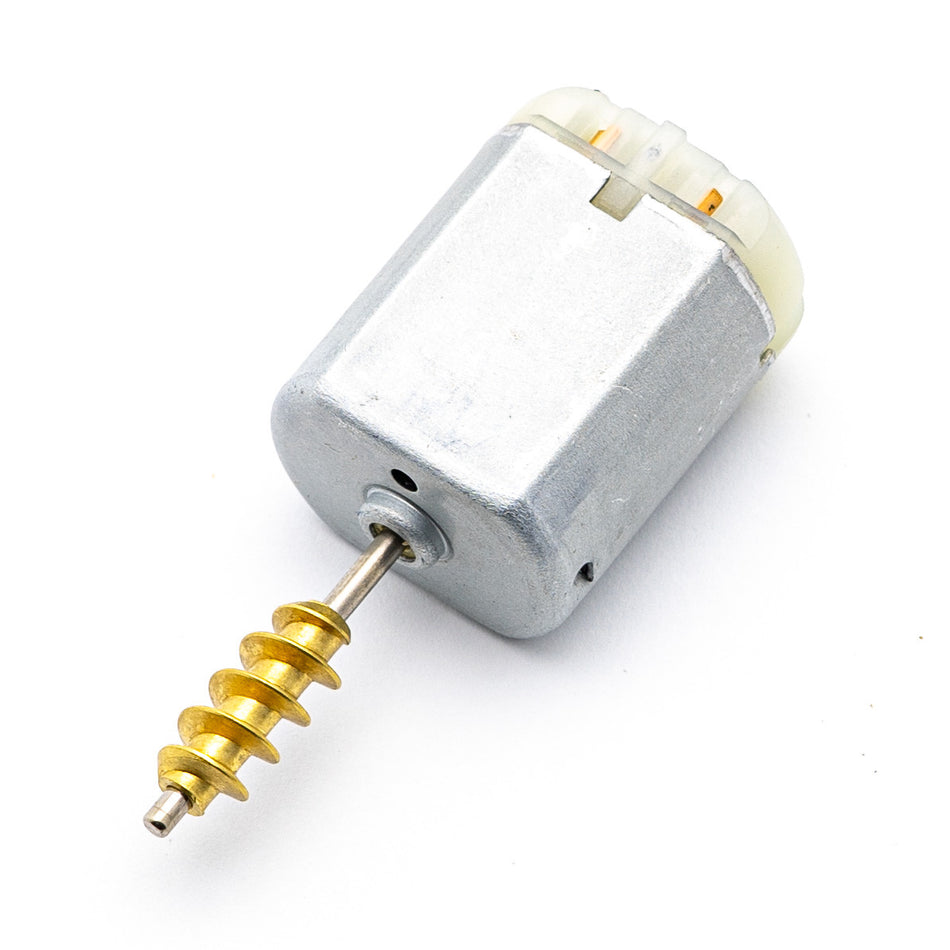

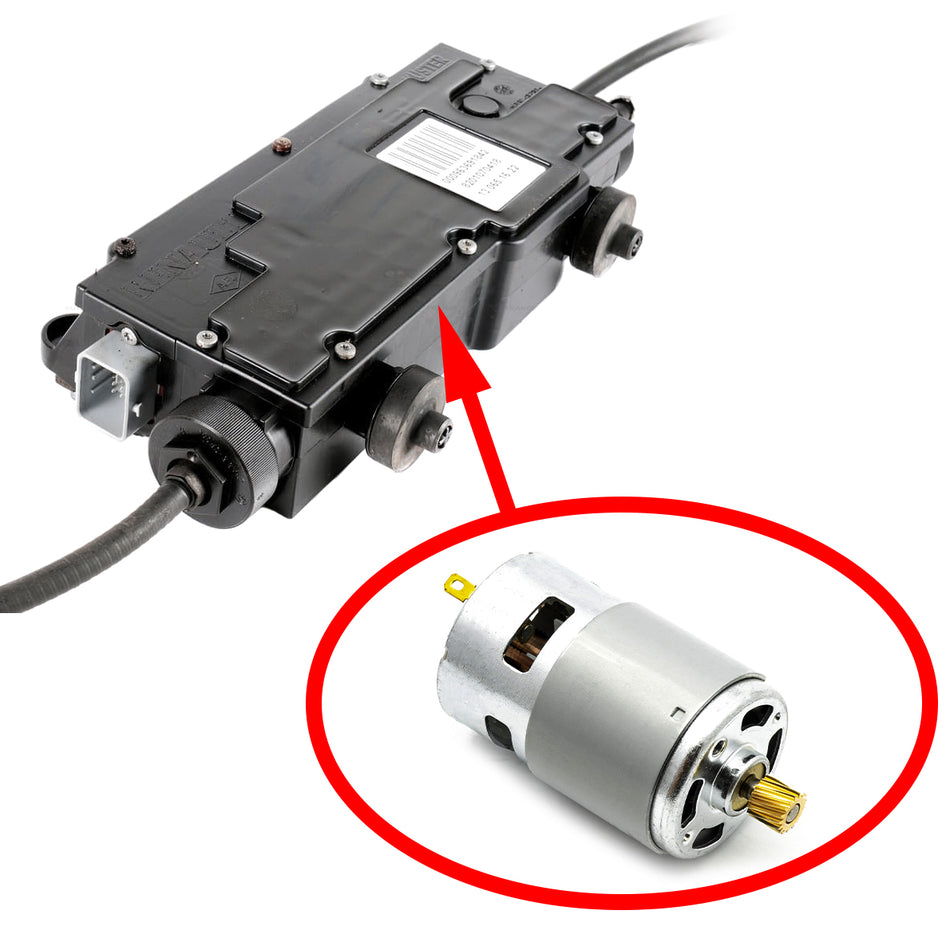

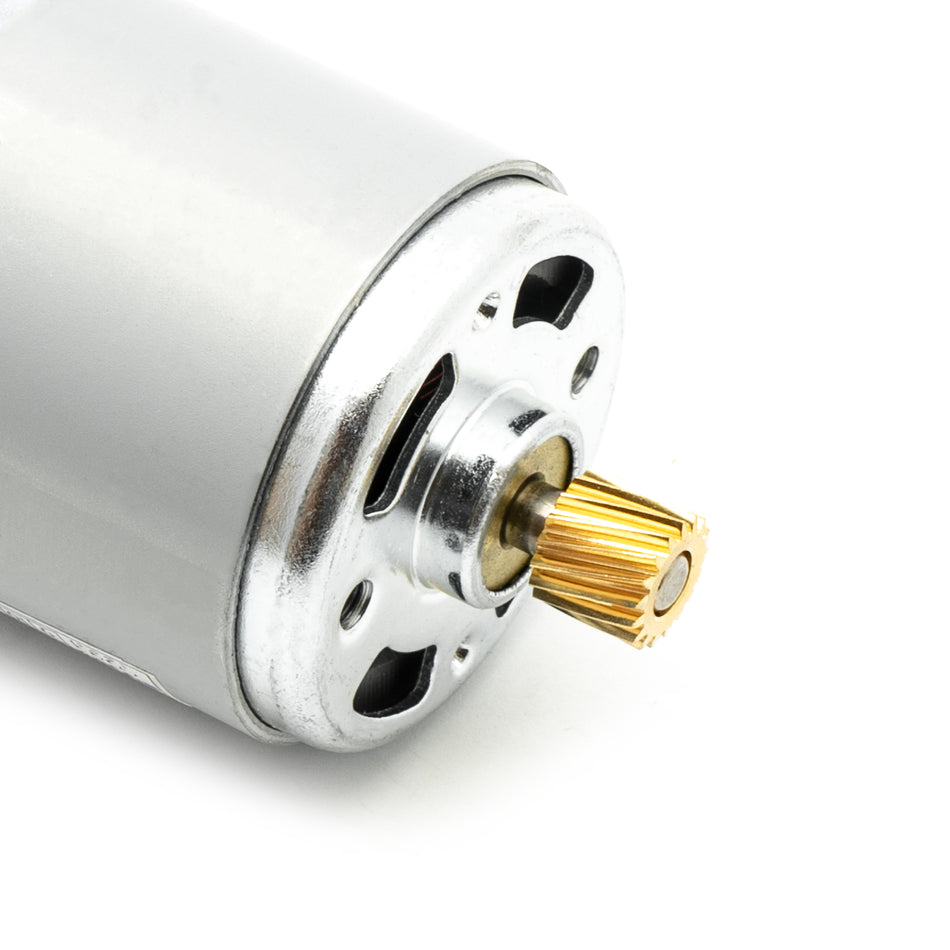

The main automotive electrical parts include the generator, starter, relays, fuses, wires, connectors, sensors, electric motors, control modules, controllers, switches, contact groups, connectors, diodes, and voltage regulators. Each of these elements performs its own function, but they are all interconnected in a single system where even a small failure can disrupt the operation of the entire vehicle.

Modern vehicles have dozens of electrical components that exchange data via CAN or LIN buses. This allows the system to control virtually every aspect of the vehicle, from turning on the headlights to operating the transmission. In such conditions, the quality of electrical components is crucial, as it affects not only comfort but also safety.

Car electrical components are classified according to their purpose. Active elements (relays, solenoids, motors) perform work, while passive elements (resistors, capacitors, diodes) stabilize current and voltage. All of them must be coordinated with each other to prevent overloads and short circuits. The stability of the electrical system depends on the cleanliness of the contacts, the correct connection of the connectors, the condition of the wiring, and protection against moisture. Even slight corrosion on a terminal can cause a voltage drop, which will affect the operation of the entire system.

Typical malfunctions of car electrical components

The most common problems with automotive electrical system components are poor contacts, oxidation of connectors, damaged wiring, blown fuses, or worn relays. Over time, electrical connections are exposed to moisture, temperature fluctuations, and vibrations, which leads to microcracks or breaks in the conductors.

Typical symptoms of malfunctions include unstable lighting, engine start failures, climate control failure, “flashing” instrument panel, or sporadic ABS system activation. Sometimes the problem lies in damage to the controller or relay, but more often it is due to simple oxidation or weakening of the contact.

Modern cars often show errors related to electrical components — even a small drop in voltage on the sensor can cause the Check Engine indicator to come on. In such cases, it is important not just to replace the component, but to find the root cause — it could be damaged insulation, a short circuit, or weak feedback in the circuit.

Diagnosing electrical systems requires special equipment. Multimeters, oscilloscopes, and diagnostic scanners that read error codes from electronic units are used to check voltage, resistance, and current. Scanners allow you to identify the specific component where the failure is occurring — a sensor, valve, relay, or wiring.

Repair and restoration of automotive electrical parts

Repairing automotive electrical parts involves restoring the functionality of a specific element or connection. For example, replacing contacts in a connector, restoring wire insulation, replacing a burnt-out relay, or installing a new sensor.

Repair kits for automotive electrical system components allow you to perform such repairs quickly and efficiently. They contain all the necessary parts for repairing harnesses, connectors, and connections. This is especially important for cars where the manufacturer does not sell individual contacts, only complete wiring modules.

automotive electrical parts affect not only comfort but also driving safety. They control ABS, ESP, airbags, adaptive lighting, tire pressure monitoring, and even the electronic parking brake. Any error or loss of contact in these units can have serious consequences.

Therefore, it is important not to ignore minor symptoms, such as periodic headlight fading or unstable instrument panel operation. This may be a sign of connector oxidation or a microcrack in the wire. Timely repair and installation of quality components ensure reliability and safety on the road.

Commonly asked questions and answers (FAQ)

1. What are the main reasons for electrical system failure?

Oxidation of contacts, damage to insulation, wear of relays, short circuits due to moisture or incorrect connection of additional devices.

2. Can a single contact in a connector be replaced?

Yes. Repair kits for automotive electrical system components are available for this purpose, containing terminals, seals, and fasteners.

3. How can I check the performance of an electrical unit?

Using a multimeter or diagnostic scanner that shows the voltage, resistance, and signal presence on each circuit.

4. Does the quality of the contacts affect the performance of the electronics?

Yes. Even a small amount of resistance due to oxidation can cause malfunctions in sensors, controllers, and safety systems.

5. How can I protect the electrical system from moisture?

Use sealed connectors, rubber seals, and dielectric grease for the contacts.

6. Are Klifex kits suitable for all cars?

Yes. We manufacture kits for most European, American, and Asian models, including BMW, Audi, Mercedes-Benz, Volkswagen, Ford, Toyota, Honda, and others.

7. How often should the wiring be checked?

At least once every two years or after any repairs under the hood.

8. Does Klifex provide a warranty for electrical components?

Yes. All Klifex electrical components are tested for conductivity and tightness, have a quality guarantee, and are OEM-level certified.

Where to buy automotive electrical and electronic components with delivery in the US?

Klifex is a company that develops and manufactures repair kits and electrical components for cars. We combine engineering precision with practicality to create solutions that help service centers in the US and around the world quickly restore automotive electrical systems. Our automotive electrical parts catalog offers a wide selection of reliable components designed to meet the needs of modern repair professionals. These car electrical components are made from high-quality materials that have been tested for resistance to moisture, temperature, and mechanical stress. We don't copy the original parts — we improve them by eliminating the weak points that lead to common failures.

We work directly with service centers and mechanics, offering kits that reduce repair time and ensure reliability for years to come. Every batch of Klifex products undergoes quality control, contact testing, and load testing.

We ship our components throughout the United States with fast online ordering. Klifex is not just spare parts, but solutions created by engineers for engineers. We help maintain efficiency and stability in every electrical system in your vehicle.

Out of stock

Out of stock

Out of stock

Out of stock

In stock

In stock